Ford 9" Axle Housing

Ford 9" Axle Housing - Oversized 1.5"- 6 UNC Inspection Plug

Couldn't load pickup availability

Description

Description

Ford 9" Axle Housing

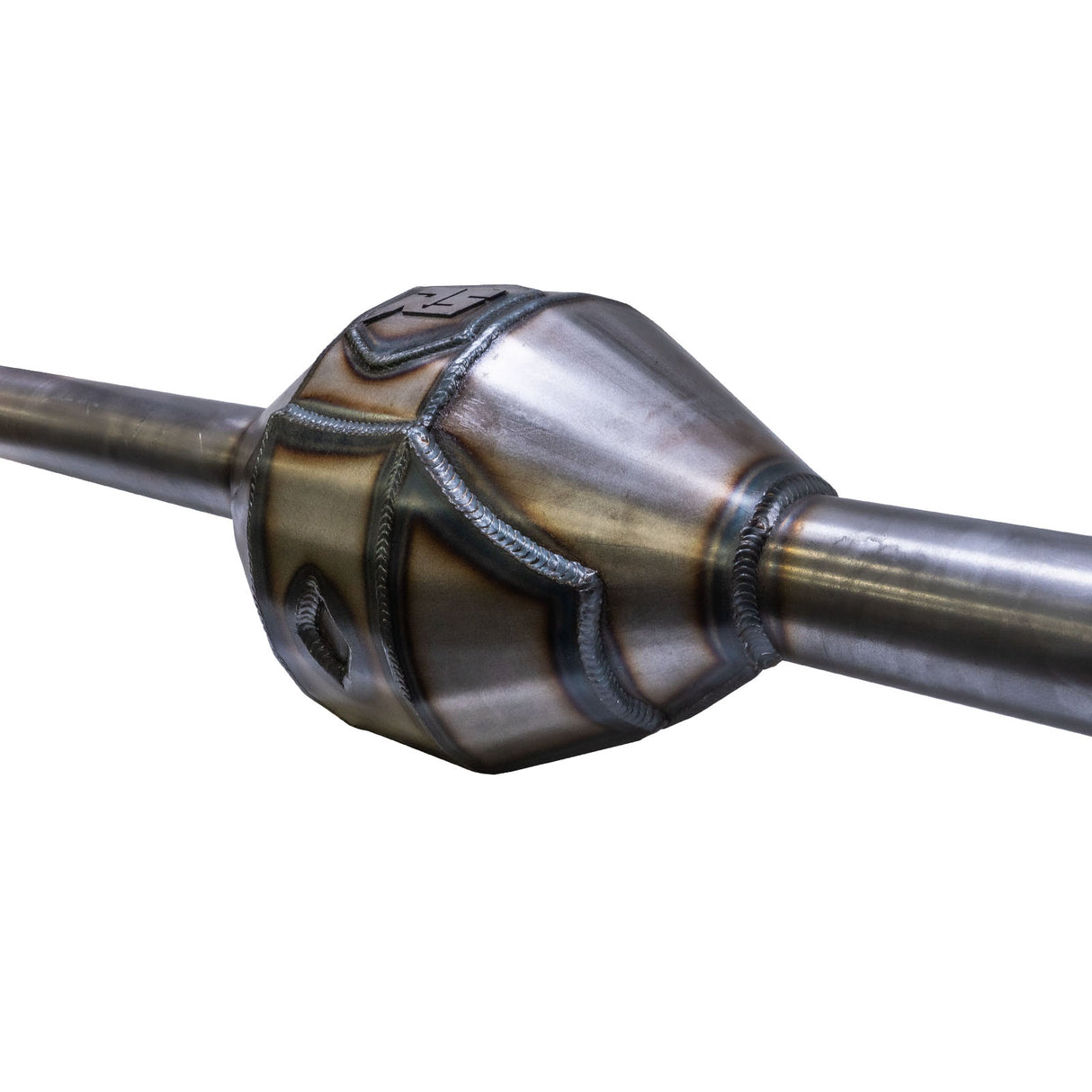

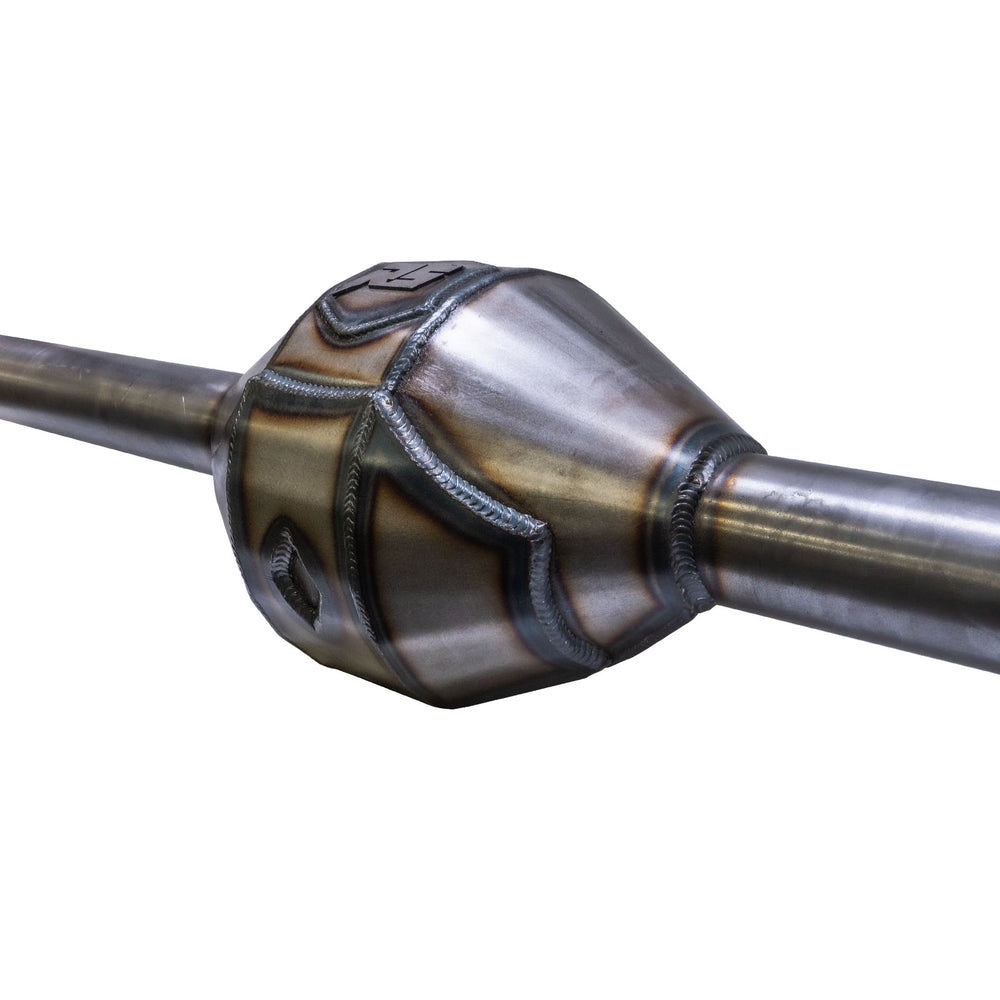

Fabricated 9" housing, 72" long with 3.5" × 3/8" DOM tubes and reinforced center

This USA-built housing uses a 3/8" face plate that’s drilled and machined flat after welding for precise third-member fit. The shell is 1/4" steel with 12 bends and added 3/16" armor in high-impact areas, plus 1/4" internal gusseting for rigidity. It accepts Ford 9" third members and allows 9" or 10" ring gear setups for high strength builds.

Axle tubes are raw 3.5" OD × 0.375" wall DOM (2.75" ID) keyed into the face plate and fully gusseted—cut to your width during setup. A weld-in 3/4" NPT fill/drain bung is included; installation requires cutting/welding, and the breather vent requires drilling and tapping (5/16"-18). Center section armor, studs, inner seal surface, and seal set screws are included to simplify final assembly.

Key Features

- Part Number: R1668

- Overall housing length: 72"

- 3/8" face plate, machined after welding

- 1/4" shell with 12 bends + 3/16" armor

- 1/4" internal gusseting ties center together

- Accepts 9" or 10" ring gear third members

- 3.5" OD × 3/8" wall DOM tubes (2.75" ID)

Specifications

- Face plate: 3/8" steel, machined post-weld

- Main shell: 1/4" steel with additional 3/16" armor

- Studs: 3/8"-24 TPI

- Fill plug (standard): 3/4" NPT with weld-in bung

- Breather vent: drill/tap 5/16"-18; brass barb included

Kit Includes

- Ford 9" bare tube housing

- Center section armor installed

- Center section studs

- Fill plug and weld-in bung (cutting/welding required)

- Inner seal surface and seal set screws

- Brass thread-in breather barb fitting (drilling/tapping required)

Available Kit Options

Note

Housing ships long at 72" and requires cutting/fixturing to your width; mock up axle ends, brackets, and pinion angle before welding. Install the 3/4" NPT bung by cutting and welding, and drill/tap the breather to 5/16"-18 as needed; verify third-member fit on the machined face before final assembly. Use proper fixturing to keep tubes straight, then complete all welds and recheck runout and stud torque prior to service.