Toyota 8.7" Axle Housing (Bare Tube)

Toyota 8.7" Axle Housing (Bare Tube)

Couldn't load pickup availability

Description

Description

Toyota 8.7" Axle Housing

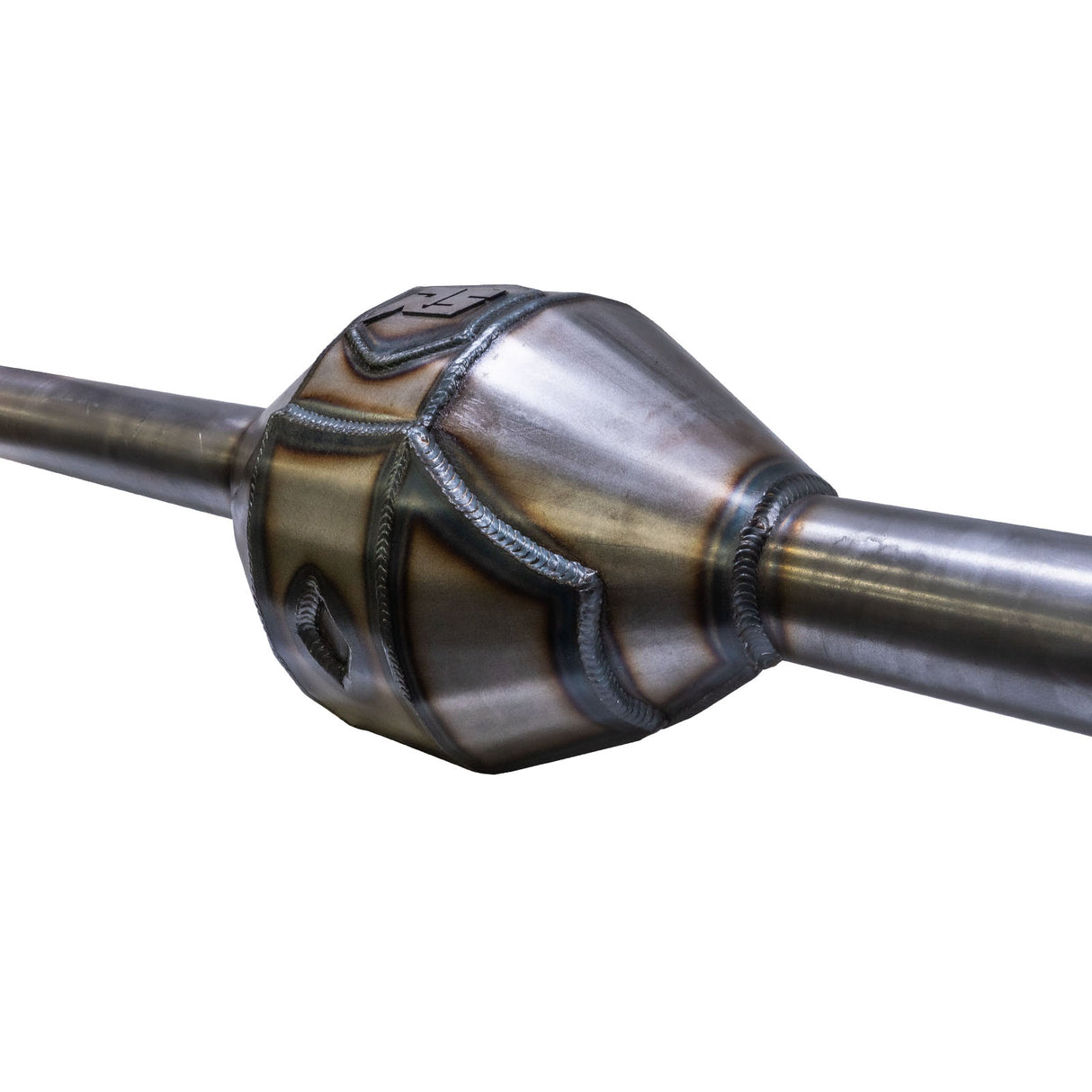

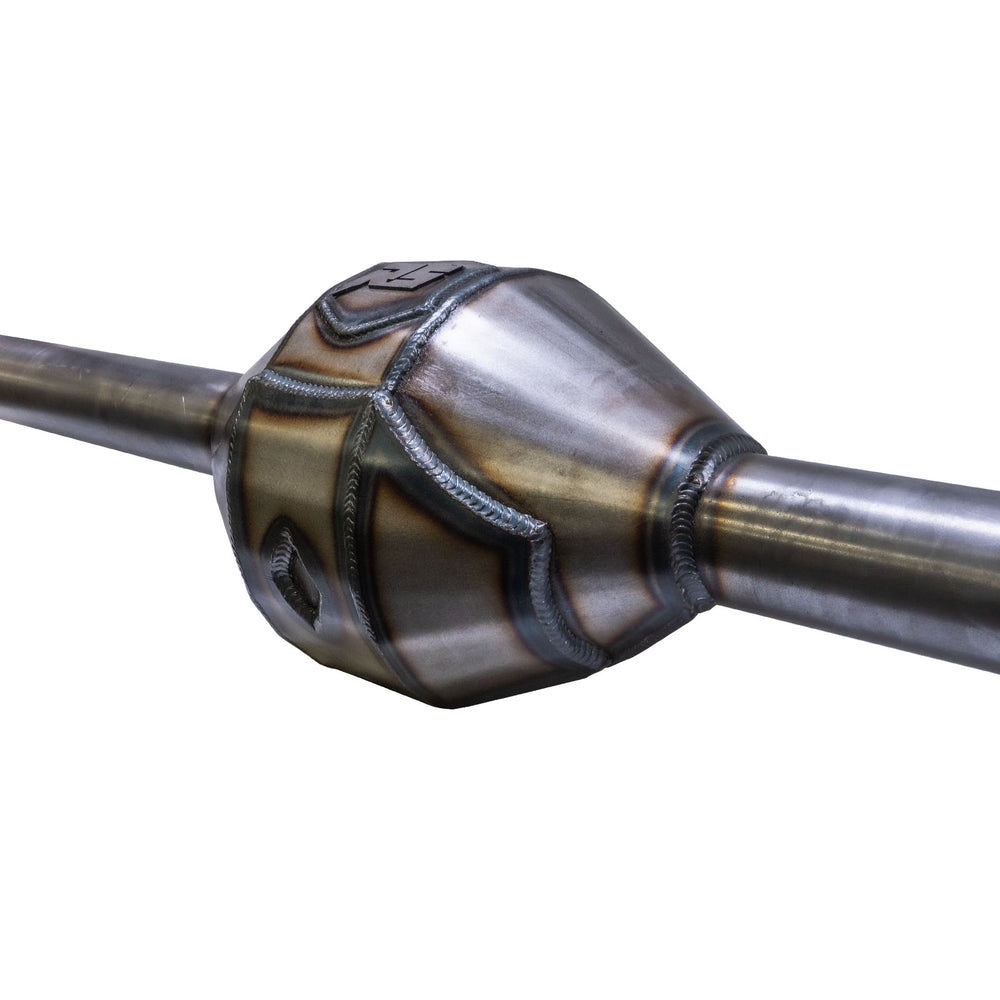

Fabricated 8.7" housing, 72" long with 3.5" × 3/8" DOM tubes and reinforced center

This USA-built housing uses a 3/8" face plate that’s drilled and machined flat after welding for precise third-member fit. The shell is 1/4" steel with 12 bends and added 3/16" armor in high-impact areas, plus 1/4" internal gusseting for rigidity, these features make RuffStuff Axle Housings dramatically stronger than other fabricated housings on the market. It accepts standard Toyota 8.7" third members.

Axle tubes are 3.5" OD × 0.375" wall DOM (2.75" ID) keyed into the face plate and fully gusseted— these are built to 72" total length so you can cut to your desired width to fit your application. A weld-in 3/4" NPT fill/drain bung is included; installation requires cutting/welding, and the breather vent requires drilling and tapping (5/16"-18). Center section armor, studs, inner seal surface, and seal set screws are included to simplify final assembly.

Key Features

- Part Number: R2873

- Overall housing length: 72"

- 3/8" face plate, machined after welding

- 1/4" shell with 12 bends + 3/16" armor

- 1/4" internal gusseting ties center together

- Accepts Toyota 8.7" third members

- 3.5" OD × 3/8" wall DOM tubes (2.75" ID)

Specifications

- Face plate: 3/8" steel, machined post-weld

- Main shell: 1/4" steel with additional 3/16" armor

- Studs: M10-

- Fill plug (standard): 3/4" NPT with weld-in bung

- Breather vent: drill/tap 5/16"-18; brass barb included

Kit Includes

- Toyota 8.7" bare tube housing

- Center section armor installed

- Center section studs

- Fill plug and weld-in bung (cutting/welding required)

- Inner seal surface and seal set screws

- Brass thread-in breather barb fitting (drilling/tapping required)

Note

Housing ships long at 72" and requires cutting/fixturing to your width; mock up axle ends, brackets, and pinion angle before welding. Install the 3/4" NPT bung by cutting and welding, and drill/tap the breather to 5/16"-18 as needed; verify third-member fit on the machined face before final assembly. Use proper fixturing to keep tubes straight, then complete all welds and recheck runout and stud torque prior to service.